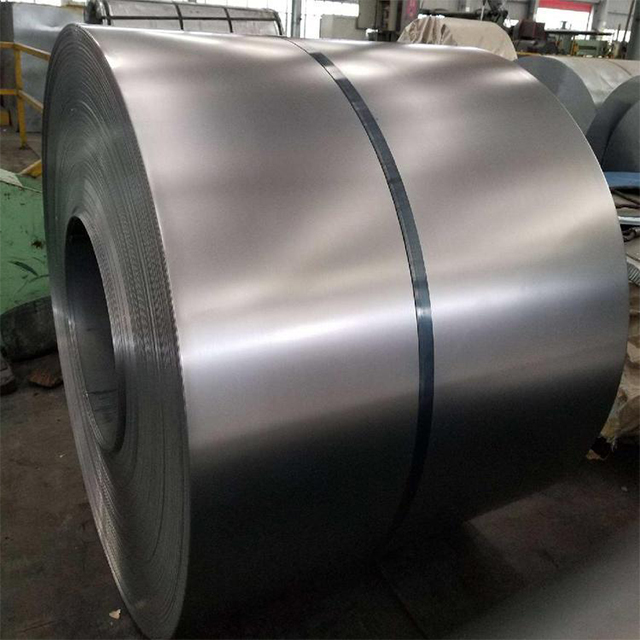

Jiugang galvanized coil production

introduction

Jiugang Galvanized Coil Production: An In-depth Analysis

Abstract:

This article aims to provide a comprehensive analysis of Jiugang's galvanized coil production. By delving into the various aspects of this process, we seek to captivate readers' interest and offer them a deeper understanding of the background and significance of galvanized coil production at Jiugang.

Text:

1. Raw Materials and Processing Techniques

1.1 Raw Material Selection

Jiugang prioritizes the selection of high-quality materials for its galvanized coil production. The company conducts meticulous research and sourcing to ensure top-notch raw materials that adhere to strict quality standards. The selection process involves rigorous testing and analysis of various parameters like chemical composition, mechanical properties, and surface finish.

1.2 Galvanizing Process

The galvanizing process at Jiugang involves multiple stages, each crucial in achieving superior quality galvanized coils. The coil undergoes rigorous cleaning and surface preparation to eliminate impurities and ensure better adhesion. It is then immersed in a molten  zinc bath under controlled temperature and time conditions. This promotes the formation of a protective zinc layer that safeguards the coil against corrosion.

zinc bath under controlled temperature and time conditions. This promotes the formation of a protective zinc layer that safeguards the coil against corrosion.

1.3 Advanced Production Techniques

Jiugang integrates advanced production techniques in its galvanized coil production to enhance efficiency and consistency. Techniques such as continuous hot-dip galvanizing and inline annealing contribute to the production of coils with superior surface quality, precise dimensions, and excellent mechanical properties. These techniques help Jiugang meet the diverse requirements of its customers across various industries.

2. Quality Control Measures

2.1 Stringent Testing Procedures

Jiugang strictly adheres to a comprehensive set of quality control measures to ensure the reliability and performance of its galvanized coils. Rigorous testing procedures include visual inspection, thickness measurement, adherence assessment, and surface quality evaluation. These procedures ensure that only coils meeting the highest standards are released for further processing or distribution.

2.2 Continuous Improvement Initiatives

Jiugang recognizes the importance of continuous improvement in maintaining and enhancing the quality of its galvanized coils. The company actively seeks feedback from customers and promptly addresses any concerns or issues. Additionally, it invests in research and development to innovate and improve its processes further. This commitment to continuous improvement is a testimony to Jiugang's dedication to producing top-quality galvanized coils.

2.3 Certifications and Recognitions

Jiugang's commitment to quality is evident in the certifications and recognition it has received over the years. The company holds certifications such as ISO 9001, ensuring compliance with international quality management standards. Furthermore, Jiugang has been recognized by industry bodies for its outstanding quality performance, further bolstering its reputation in the galvanized coil production sector.

3. Applications and Market Reach

3.1 Diverse Applications

Jiugang's galvanized coils find extensive applications across various industries. The automotive sector extensively utilizes these coils for body panels, structural components, and underbody parts. The construction industry relies on galvanized coils for roofing, walling, and structural elements. Additionally, other sectors like appliances, transportation, and agriculture also benefit from the exceptional properties of Jiugang's galvanized coils.

3.2 Global Market Presence

Jiugang has strategically positioned itself as a leading provider of galvanized coils in both domestic and international markets. Its dedication to quality and customer satisfaction has allowed the company to expand its market reach and forge partnerships with global players. Through collaborations and an extensive distribution network, Jiugang has established itself as a trusted supplier of galvanized coils worldwide.

3.3 Future Market Prospects

The galvanized coil market is expected to witness significant growth in the coming years, driven by rising infrastructure development, growing automotive production, and increasing demand for corrosion-resistant materials. Jiugang is positioned to capitalize on these opportunities by leveraging its expertise, high-quality production capabilities, and commitment to innovation. Expanding its product portfolio and exploring emerging markets will be crucial for Jiugang to seize future market prospects.

Conclusion:

In conclusion, Jiugang's galvanized coil production represents a remarkable blend of advanced techniques, stringent quality control, and extensive market reach. By investing in research and development, maintaining a relentless focus on quality, and forging strategic partnerships, Jiugang has established itself as a prominent player in the global galvanized coil industry. Moving forward, Jiugang must continue to innovate and adapt to meet evolving customer demands and emerging market trends to solidify its position as a market leader.

Leave a Comment